Coconut charcoal hookah or coconut shell charcoal is a burning tool used to burn Arab shisha. This shisha charcoal is produced using mature coconut and other ingredients without the addition of chemicals. Coconut charcoal is known as a food-grade burning tool or can be used to burn food without producing a strong odor and different taste. Additionally, charcoal made from coconut is also considered more environmentally friendly, producing heat faster and more stable, and its usage is more durable compared to firewood.

Hookah or shisha users certainly need an important component, which is charcoal used to heat the tobacco. In the hookah burning process, a stable heating level and a neutral odor are important for burning hookah properly. The basic material used to make coconut charcoal for hookah is high-quality coconut that has been compressed and considered a natural and environmentally friendly material because no chemicals are added to it.

Unlike charcoal made from wood or sawdust, coconut shell charcoal is produced using renewable energy and does not produce much ash when burned. Additionally, coconut charcoal for hookah also has a longer burning time and relatively high temperature compared to traditional charcoal. In other words, this type of charcoal requires less charcoal in each burning session.

The Manufacturing Process of Coconut Charcoal Hookah

The process of making coconut charcoal specifically for shisha is not much different from making coconut charcoal for other uses. Basically, this renewable energy charcoal is made from coconut without the addition of chemicals. The production process of coconut charcoal hookah is carried out in several stages: carbonization > charcoal grinding > mixing with binding agents > compression of hookah charcoal > drying > packaging of hookah charcoal production.

The manufacturing process of coconut charcoal hookah is a combination of skills, knowledge, and the right use of technology. To get high-quality coconut charcoal hookah, processors must pay attention to the materials and the process of making coconut charcoal hookah properly. Here is a brief overview of the process of making coconut charcoal for shisha:

1. Selection of the Best Coconut

The first process carried out by coconut charcoal processors is to determine the best and most appropriate coconut selection to produce high-quality charcoal. Coconuts used to make high-quality coconut charcoal usually use mature coconuts. In this process, charcoal processors must pay close attention to the quality of the materials used. Fresh and mature coconuts are still the best ingredients for making coconut charcoal for shisha.

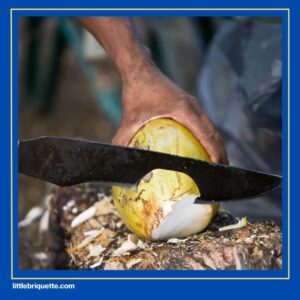

2. Peeling the Coconut Shell

After finding the best coconut, processors can continue the process of peeling the coconut shell to access the coconut meat inside. In this process, processors can use special tools or manually using a machete.

In the process of peeling the coconut shell, make sure that the coconut meat that will be used as the basic material for hookah charcoal can be accessed properly. The selection of mature coconuts for this basic material is because of the abundance of coconut meat and its density level, which will make hookah charcoal of high quality.

3. Cutting and Cleaning the Coconut Meat

After the process of peeling the shell with its meat, processors can cut and clean the coconut meat. Cutting the coconut is done to produce small pieces to facilitate the next process. After being cut into small pieces, make sure the coconut meat is washed clean to remove dirt and other residues that can reduce the quality of coconut charcoal.

The process of cleaning coconut meat can be done periodically to achieve maximum cleanliness. This is because the cleaner the coconut meat used, the better the quality produced. Therefore, it is important to pay attention to step-by-step cleaning processes.

4. Drying the Material

After the coconut meat is cut into small pieces, the next step is drying. This drying process is done by neatly arranging the pieces of coconut meat and letting them dry under the sunlight, which usually takes several days. This burning process is useful for reducing the moisture content in the pieces of coconut meat and producing suitable raw materials for burning shisha with high quality.

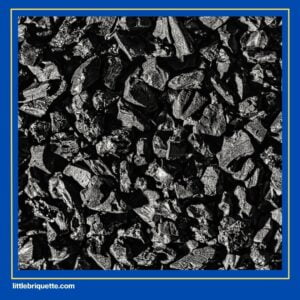

5. Burning the Coconut Charcoal Material

When the pieces of coconut meat are completely dry, the next step is to burn the coconut meat. This burning process is done by putting the pieces of coconut meat into a furnace or other burning tool. To produce high-quality charcoal, this burning process must be carried out in a controlled condition without any air entering. The burning process of coconut charcoal hookah material is done at a high temperature, and the burning process may take quite a long time.

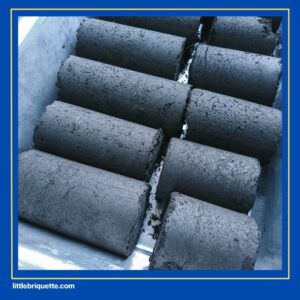

6. Compacting and Cooling the Material

The next step is compacting and cooling the coconut charcoal that has gone through the burning process. This compacting process is done to help increase the density of the charcoal and ensure that the coconut charcoal has high quality, which is evidenced by its strength and durability. To compact the coconut charcoal, processors use mechanical pressure to produce a perfect compact.

After the coconut charcoal goes through the compacting process, the next step is cooling. This process is done to reduce the temperature and ensure that the coconut charcoal for shisha is no longer hot. This step is done before the packaging process and marketing to users.

7. Filtering and Packaging Coconut Charcoal Hookah

The final step in the process of making coconut charcoal hookah is filtering and packaging. This filtering process is done to remove dust, small particles on the charcoal, or other foreign objects that may still be attached and disrupt the quality of coconut charcoal.

After filtration, the charcoal is then packaged using suitable packaging, such as plastic bags, cardboard boxes, which will then be marketed to users. The packaging process must be ensured to be done properly to maintain the quality and provide an attractive appearance to consumers until they make a purchase. High-quality coconut charcoal will produce clean smoke, a non-pungent odor, consistent taste, and provide a satisfying shisha smoking experience.

Best Suppliers of Coconut Charcoal Hookah

Considering the complicated process of making coconut charcoal hookah if not done by professionals. Currently, there are suppliers of coconut charcoal for hookah burning that are best and certainly have high quality. Getting high-quality coconut charcoal hookah will certainly enhance the shisha smoking experience. Therefore, trust to buy high-quality coconut charcoal hookah at Little Briquette. You can buy and get more complete information by contacting the contact here.