Understanding Raw Coconut Supply Chain Process – The journey of coconuts charcoal briquettes from the farms to your customer’s tables involves many different people and steps. It starts with farmers who grow the coconuts, then some scavengers help collect them from different places. After that, the coconuts are burnt before being sent to companies where we produce briquettes. It’s like a big team effort to make sure the supply chain is stable.

Table of Contents

ToggleThis supply chain can affect the briquettes price, also its supply quantities. Factory with a good supply chain management will have a stable price. While factories with bad supply chains will have a fluctuating price.

Coconut supports the “blue economy” by creating jobs and using resources wisely. Blue economy means using every waste of coconut to become a product for sale.

Almost every part of Coconut can be used in our life. It’s like a “Swiss Army Knife” for example, such as a coconut shell that can become briquettes, also coconut husk can become cocopeat, coconut fiber for a mattress, the water can become a drink with original flavor or with variant taste, the coconut also can become Chopra, the meat can be topping for dessert, etc.

This makes coconut an eco-friendly product, The benefit is to use every part of the coconut to not be wasted and to transition from some other materials that are not friendly for the ecosystem and change it with just coconut parts.

For example, if we use hardwood charcoal, we can save the environment by transitioning to coconut charcoal instead.

Because for me, it’s just a waste if people have to cut trees, destroy green plants, damaging the ecosystem, just for the woods to be charcoal.

For me, it is more useful if the wood is used for any other aspects.

Using coconut charcoal briquettes helps to save the environment by using a renewable resources and helping to save a tree. Every 1000 kg of coconut charcoal briquettes made can save up to 75 trees.

So instead of cutting down trees. This can contribute to saving trees and preserving natural habitats.

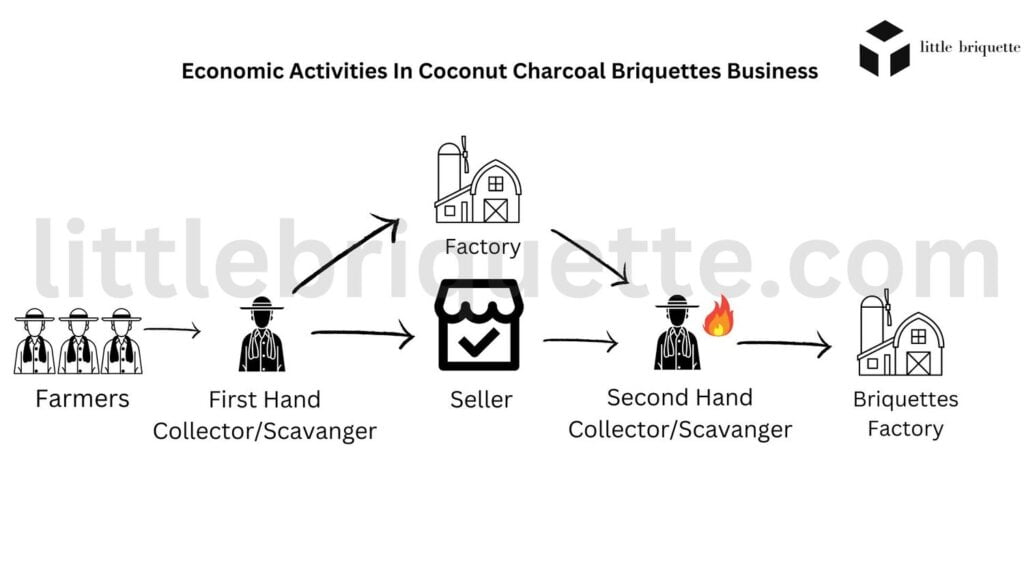

These are common supply chains of raw coconut materials until coming to a supplier factory.

The coconut raw material supply chain involves several key participants. It begins with the Farmer who cultivates and harvests coconuts. Scavenger/Collector 1 collects fresh coconuts from various sources.

These shells are then sold to the Salesman, who may be used for selling coconut drinks. Whether coconut drinks are straight from the fruit or also mix with variant flavors. The water also can be for nata de coco.

The meat also can be for making cakes, desserts, drink toppings, and can also be for copra, etc.

After it’s used, then scavenger/collector 2 will collect the waste coconut shells from the salesmen, they also can collect it from the manufacturers that don’t need the coconut shells.

After that, scavenger 2 has two choices. Whether they sell the coconut shell to a coco fiber/cocopeat manufacturer or sell it to a charcoal briquettes manufacturer.

If they sell it to a coco fiber supplier, they do not need to burn the coconut shell. If they sell it to a charcoal briquettes factory, they can burn it or give it to another scavenger that burns the shell to charcoal.

And then after that, they can sell the coconut shells charcoal to the briquettes factory so it can be processed to become coconut charcoal briquettes.

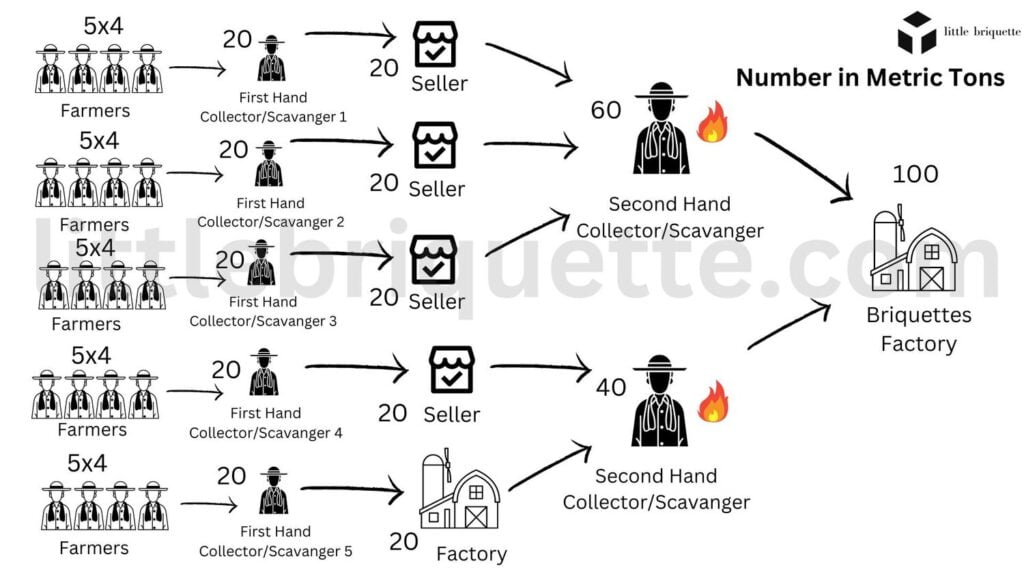

This is an easy example, so if we look at this, you can see the example of each Metric Ton they produce/collect. If it’s in the real world, they have a difference in production/collection. Some of them have a larger supply than the other ones.

Let’s say the briquettes factory needs 100 MT of coconut shell/month, 1 Farmer produces 5 MT, 1 scavenger collects 20 MT, and 1 salesman uses 5 MT.

Then we need 4 farmers for 1 scavenger, this means that with 1 farmer 5 MT each, then we need 4 farmers to get 20 MT and meet the scavenger demand.

After that, the scavenger will resell it to 4 salesmen with 5 MT each or can resell it with all of 20 MT to manufacture that used the water, or just the meat.

After they take away the water and meat, or any other parts except the shell. Another scavenger buys it with a larger demand, they will collect it from the salesman or also the manufacturer.

If they sell the shells to coco fiber/cocopeat manufacturers, they will resell them again without having to burn the shells.

But if they sell it to a charcoal briquettes factory, then they need to burn the shells so it becomes charcoal. If they burn it, they can resell the shells with a higher price margin.

After that briquettes factory buys their charcoal shells and then process them to become briquettes, and then sell them to their customers around the world.

The briquettes factory cannot work directly with farmers, because farmers can’t supply all of the briquettes factory demand.

if possible, the factory needs dozens of farmers to work with them. It is not effective because the supplier cannot manage lots of farmers, they have to share their focus on production and managing farmers.

And it is not good, because the factory will have bad operations and will give an the outcome of bad quality or even can go to lack of coconut briquettes. And with the lack of briquettes, the factory can cancel the shipment making the importers waste their money and time.

Farmers also supply coconuts whose quantity is uncertain. In some moments, they can somehow supply 5 MT, can also 3 MT only, or even 2 MT only, and so on. That is why the factory needs scavengers/collectors because they will collect the supplies as much as they can to fulfilling the demand.

Again, if the factory buys directly from the salesman, the factory needs dozens of them. It is not effective because the supplier cannot manage lots of salesmen, they have to put their focus on production.

It will be not good if the factory has to manage lots of parties, while there also producing. Their supply chain will not be effective and they will have bad business operations, and will make the product not great. Can be a bad-quality briquette or even a canceled order.

They can and maybe will make the cost more effective because the supply chain doesn’t have a long process.

But few first-hand scavengers sell directly to briquettes factory because they fulfill the salesman’s demand or other manufacturers.

Maybe they can sell directly to the charcoal briquettes factory, but it needs also experienced scavengers who can burn the coconut shells.

Burning coconut shells also need quality control such as less moisture, less ash, high calorie, and clean, and comes from an old coconut.

So if scavenger/collector 1 wants to sell directly to the charcoal briquettes factory, they need to make sure their coconut shells charcoal quality is meet the standard.

We also want the coconut water/meat not to be wasted. So with firsthand scavengers selling their coconut to salesmen, they can use them for use the water/meat of coconuts, and the shells can they sell it again to second-hand scavengers.

This is the benefit of the “blue economy” The benefit is to use every part of the coconut to not be wasted. And can use it to be a valuable product.

So, most briquette factories also stock their coconut supply in bulk. Coconut supply cannot be expired, and they will save it properly by closing the air circulation.

With stocking, they can prepare their supply if there is an issue in their supply chain. Whether it’s from the scavengers, salesman, or farmers. They will have risk management.

They can have a backup supply, so if their supply chain is lacking, they can produce their product with this backup supply. And the qualities will be the same and meet their customer standard.

Factories buy the coconut shell charcoal backup supply from days to days before they start production.