There are 2 main types of packaging for coconut charcoal:

Table of Contents

Toggle1. Inner Box/Small box

2. Master Box/Big box

The inner box is a small package that comes in a small various sizes, importer usually requests a size from 500g, 1 kg, 2 kg, and 5 kg kg. But if you want your packaging to have different sizes and customs, usually suppliers can do exactly what your inner box size request, some importers request 1,5 kg, 3 kg, 4 kg, and so on.

Each packaging size, they all have different pieces of briquettes. Logically, the larger the packaging, the more pieces, but the quantities also depend on the briquette shape and size, the larger the briquettes, the fewer the pieces.

The inner box is mainly used for marketing purposes, importers usually request inner box packaging to put their brand in their package and resell it to their market, this packaging is commonly used for importers who sell their products B2C, so they need a brand recognition to compete in their market.

The inner box is also for safety, but the inner box is not a “must have” packaging for your imports, briquettes also can be sent just by master box or big box, if importers do not need an inner box, usually because they sell it B2B.

But again, it all depends on your market demographic and behavior, because your market may be different than others.

Again, it depends on your market, if you have to compete with a brand reputation, then the inner box is worth it.

But if you just sell your charcoal bulks, and no need to brand them, you can just import the products with a master box.

You can ask your supplier if their price already includes the inner box or not, but commonly professional suppliers must include their price also for the inner box.

The inner box is increasing the price by about 100 USD / MT, so if you want to import with less cost, you can request to import the products based on just the master box.

There are several things you need to learn about the inner box:

Almost all inner box printing is full color, you can put your brand logo, the product specs, or even put your business contact such as phone number or social media. You do not have to worry, because we will guarantee your business privacy.

In the middle east, most of them also request to make their packaging in the Arabic language.

You can also mention your product is 100% coconut, with no smell, no chemicals, and any other of your product advantages, allowing you to have a unique selling point for your market.

In every inner box, we include inner plastic for each inner box size. If you have a request for a 1 kg inner box, we will not put the products without the 1 kg inner plastic, this allows your products to be more safety and your packaging clean as well.

The process of putting inner plastic in small boxes and big boxes can be different (will be explained after). And inner plastic is not gives effect to your inner box quantities, because they have a thin width.

Inner plastic is mostly transparent, yellow, or light blue. But most charcoal importers request transparent plastic, so it looked more clean and elegant.

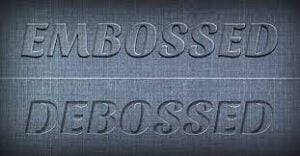

Embossing is a high-printing finishing technique that creates a raised effect on specific parts of the box surface. The reference for embossing comes from a metal template created through etching or engraving, known as a die. This die consists of two parts:

Embossed portion

In embossing, when we say something is “embossed” it means that specific areas on the boxes are made to stick out a bit, creating a slight bump or elevated effect.

Debossed portion

On the other hand, when something is “dembossed”, it means that certain parts are made to go inwards, creating a little indentation or dip in the paper’s surface.

Silica gel is a particle of material that is used to absorb moisture, so the briquettes can have a stable temperature and can protect the briquettes from lightening up, and protect the goods from mushrooms or mildew.

We put the silica gel in each inner plastic, and it does not affect the quality of the briquettes.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved protection and the appearance of the box.

Laminating is used for the outside of the box, we do not put it inside because their already inner plastic, and it already gives good protection.

And laminating is also used for elegancy, so putting it outside is good for the packaging display and appearance because it looks more professional.

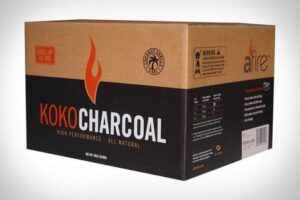

The master box is a big package that comes in a big various sizes, importer usually requests a size from 10 kg, 12 kg, 15 kg, and 20 kg. But if you want your packaging to have different sizes and customs, usually suppliers can do exactly what your master box size request, some importers request a 5 kg master box, 8 kg, 30 kg, and so on.

Unlike the inner box, the master box is calculated for the container fill, the boxes have to fit in the container so they are no waste of boxes.

If briquettes send by 20ft container, then 1 container can contain 16-18 MT.

Let’s say you want to import with a 10 kg master box and can fill 18 MT, then there will be 1800 master boxes inside. If you want to import 20 kg, then there will be 900 master boxes inside. But again, it all depends on your briquettes and your request.

There are 3 types of packaging with a master box:

This type is commonly used when it comes to importing coconut briquettes.

For example: 10 of small plastic for 1 kg, 10 of 1 kg inner box, 1 master box of 10 kg

For example: 10 small plastic for 1 kg, and 1 master box of 10 kg

This type is used for selling B2B, they sell it per 1 kg, and if they want to put their brand, we can put their logo sticker in their inner plastic, or by printing the master box.

For example: 1 big plastic for 10 kg, and 1 master box of 10 kg.

In this type, we put the products all into the big plastic, we can put it orderly or we can put it loosely, it depends on customer request.

And for this type of packaging, they do not need a brand logo on their plastic, but they just need a print in their master box. Most of it sells for B2B.

As we mentioned earlier, the master box is more for safety. And for collecting products or small packaging in a larger capacity, to have an effective inventory and calculation.

The master box is a must-have for export coconut briquettes, especially for the type of packaging that does not need an inner box. Most of them that don’t use inner box are selling to the B2B market, they do not need brand awareness, they just need business partnerships and relations.

There are several things you need to learn about the master box:

There are 3 types of printing master boxes:

Black and white is a regular printing, and it is used for your logo printing in the master box.

So commonly we used a brown carton box and then printed in black or white logo.

Uv full-color printing means we print the box with more than 3 colors, there are also 2 methods for this uv printing:- Side Printing

– Complete Printing (Side, Upper, and Lower)

If you want to request uv printing, suppliers will add more of their price to do this. So you can ask the supplier for the detailed price of your design.

And for the printing method, side or complete printing is not a big case, it is based on what you like, if you prefer to have a good display, you can use complete printing. If you want your packaging to be elegant or simple, you can use side printing or even just black and white.

Plastic covers are printed in more than 3 colours also, this cover is a rolled printed box on craft paper. This type of printing is cheaper than uv printing, and it still looks sketchy on the eyes.

This finish has less width, because it’s just rolled, and can be done both in matt and glossy variants.

As we mentioned earlier, there are three types of packaging with a master box.

For the types that do not need an inner box, we can put a small plastic for 1 kg or big plastic for 10 kg. This all depends on your request.

If you request 1 kg, you can also put your brand logo on the inner plastic with stickers. But if you use 10 kg of inner plastic, you can just focus on your brand in the master box.

Inner plastic is mostly transparent, yellow, or light blue. But most charcoal importers request transparent plastic, so it looked more clean and elegant.

A single-wall master box is made from a single layer of corrugated cardboard. In a single-wall box, there is only one layer of fluted cardboard, sandwiched between the two liners. This design provides basic protection and is suitable for products that don’t require heavy-duty packaging. Single-wall boxes are a practical choice for lightweight boxes.

Picture a double-wall box as a tougher version of the single-wall box. It has two layers of strong cardboard with wavy lines in between. This makes it stronger and more durable, which is helpful for heavier items or when things need to be transported over longer distances.

In addition, walls do not give effect to the briquettes pieces. Choosing between a single-wall and double-wall master box depends on factors such as the weight of the briquettes, the distance they need to travel, and the level of protection required. If you’re shipping larger quantities of briquettes over longer distances, a double-wall master box would provide better security and durability, ensuring your product arrives in optimal condition.

We do not recommend you unless you import “coconut shell charcoal”, coconut charcoal briquettes are shaped, and if just with bags of plastic, then it will have a high potential to be cracked.

Charcoal is also a dangerous goods product, it needs a vanning survey and strong regulations for protection such as many certifications and addition for the container (thermal blanket, check container temperature, and so on).

We are a Private Label Manufacture/OEM Manufacture, we can produce coconut charcoal briquettes specifications according to your request. We can also make a custom coconut charcoal briquettes shapes and sizes, and also custom packaging with under your brand!